Degassing and decontamination is a single step process designed for fast and efficient—and therefore economical—process plant cleaning.

Using an enhanced steaming technique in which chemicals are injected into the steam stream, we are able to clean large process vessels, reactors, exchangers, and interconnecting piping. Degassing and decontamination is most often used for post-operational cleaning to remove H2S, benzene, LELs, pyrophoric iron, mercaptans, and ammonia.

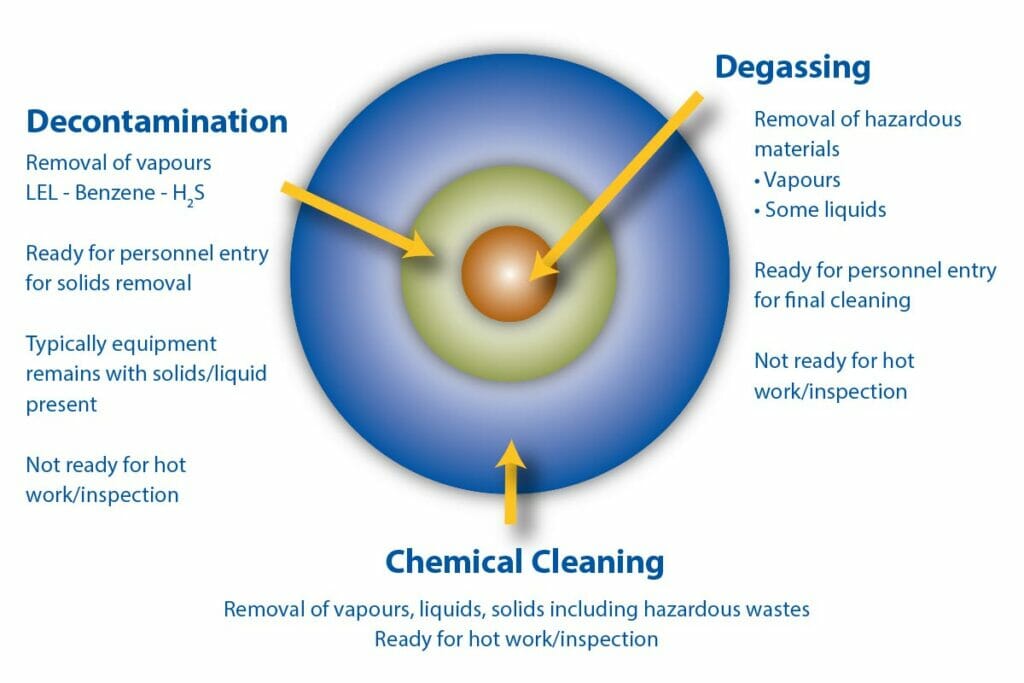

Degassing is a chemical cleaning technique that reduces the hazards of dangerous gaseous elements inside petro-chemical processing equipment. To improve the degassing process, it is often recommended that decontamination (solvent circulation) precede degassing to minimize the source of contamination (e.g., sludge, heavy deposits, etc.). Using FQE® Chemicals specially designed chemicals can provide a safe environment for vessel maintenance. This process reduces both the amount of waste and human exposure to dangerous substances during cleaning and maintenance work.

Learn more about degassing chemicals

More Degassing & Decontamination Content

Degassing

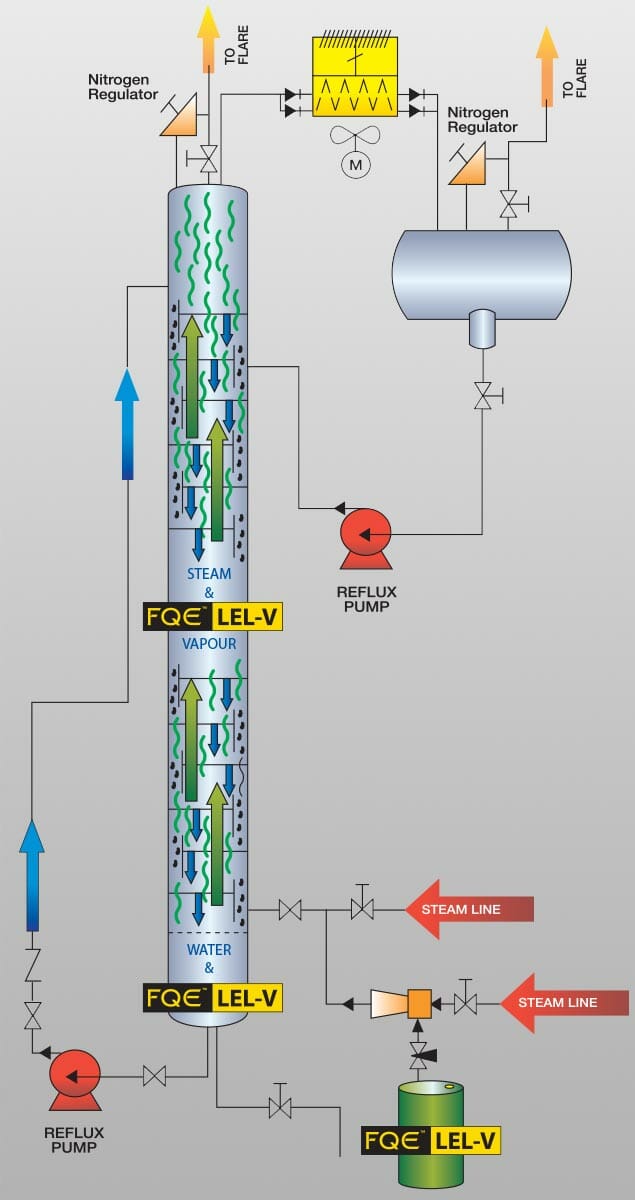

Degassing requires a preparatory injection of plant steam into the vessels to bring the system temperature up to a sufficient level (~90oC) in order to increase the effect of the chemistry and ensure that the maximum amount of organic material will be removed. The higher temperature helps loosen any of the system contaminants and expedite their removal. The chemistry, mixed with the steam, travels upward through the vessels before condensing and cascading down the vessel walls. In order to confirm proper chemical distribution, the chemistry should be exiting from both the top of the vessel with the steam, and from the bottom of the vessel as condensate.

The precise steam flow rates and combined chemical injection rates that are required are determined during the detailed engineering and procedure generation process. Steam phase cleaning can target the removal of LELs, H2S, iron sulphide, ammonia, and mercaptans.

Explanation of Points and Results