FourQuest Energy provides a large range of fluid filtration services, from ensuring large particulate is filtered out of testing water to provide reverse osmosis filtration for boiler feed water.

We also provide microscope particle analysis of filtered fluid to guarantee that it meets the customer’s cleanliness standards, including (but not exclusive to) ISO 4406 and NAS 1638.

Bag Filtration

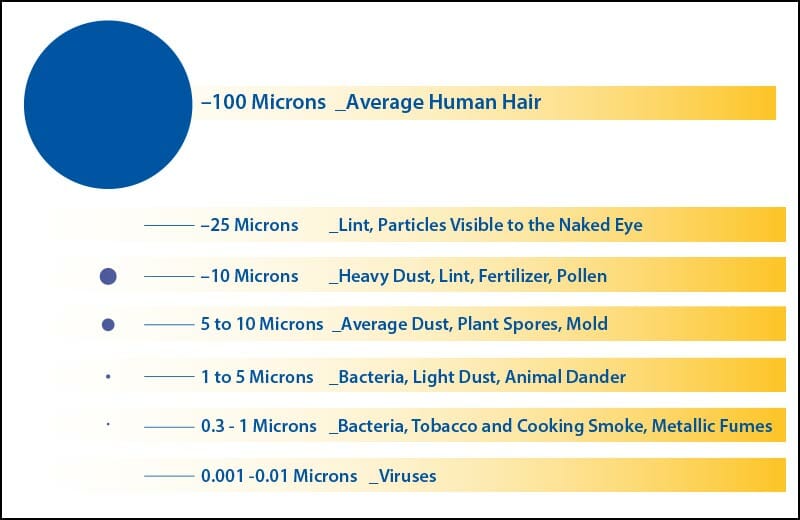

Bag filtration is an economical filtration method consisting of three components: a pressure vessel, micron rated filter bags, and a filter bag retainer basket. Filter bags vary from 1 micron absolute to 100 micron nominal, depending on customer request. The filter bags are highly efficient: 99% for absolute filter bags and above 80% for nominal bags. FourQuest has several sizes of bag filtration equipment from single bag filter pots to triple vessel 18-bag filtration skids; we tailor our equipment to best suit your project.

Reserve Osmosis Filtration

The FourQuest Energy reverse osmosis skid provides a high quality water purification solution. It is commonly used in plants for demineralizing water for boiler feed water applications. We provide boiler feed quality water before a permanent treatment plant is operational, which helps to kick start the operation of the plant’s water treatment facilities. Reverse osmosis solutions can also be provided during plant operation to supplement water supplies or to provide water during a treatment plant shutdown.

Related Industry Insight and Case Study

Coalescing Filters

Water contamination is one of the most common and one of the most damaging issues in a hydrocarbon fluid system. It can cause serious problems such as effecting system production processes by changing conductivity, increasing bacterial growth, and fouling equipment. FourQuest Energy coalescers are specifically designed for removal of emulsified water from hydrocarbons. Mechanical coalescers employ filter media to make droplets coalesce. This technology is ideal for separating hydrocarbons from water and vice versa.

Applications Within the Energy Industry

Providing filtration for glycol startup and circulation

Glycol is used as a heat transfer medium on many plant sites and in smaller piping for unit heaters and air handling units. Prior to commissioning and startup, it is critical to remove contaminants such as debris, scale, and other particles that could potentially be present in the pipe. These contaminants increase the likelihood of heat exchanger and equipment failure by reducing efficiency and ultimately plugging the system. Glycol systems are typically very large, complex, and have many loops. It is essential to provide clean glycol to all parts of the system in order to avoid risk of equipment damage. We provide temporary glycol filtration by supplying filtration skids and a wealth of filtration experience to ensure efficient system start up.

Meeting requirements for product cleanliness

Permanent facilities in the energy industry are not always equipped to handle pipeline contamination such as scale, debris, water contaminants, etc. At times the customer’s products may not meet specifications due to these contaminants. FourQuest can be counted on to provide filtration services and ensure the product meets customer specifications.

Maintaining cleanliness of water for testing

Maintaining the cleanliness of water is essential for basic plant operations in order to keep pipes clean and protect equipment from potential harm. It is critical to remove coarse particles when performing hydrostatic pressure tests on tanks, pipelines, etc. Bag filtration is a very simple, yet effective method to ensure all water being used for testing is cleaned to the customer’s specification.

Demineralizing water for boiler feed water applications

Most plants—specifically water treatment and SAGD (Steam Assisted Gravity Drainage) plants—require high quality boiler feed water for their operations. Our reverse osmosis skids have been used in the past with great success to acquire high quality boiler feed water for SAGD projects. These state-of-the-art skids are effective in demineralizing water for any boiler feed water application.

Oil removal from produced water

FourQuest Energy coalescing filters are ideal for the removal of petroleum and hydrocarbon products from produced water and for trace contaminant removal from intermediate products in oil refineries. We can also provide temporary solutions for oil/water systems.