The importance of filtration in the oil and gas industry is often underestimated. Visual inspections of the inside of equipment can be very difficult, and many particles that would potentially be captured by filters escape the naked eye.

Beyond that, equipment downtime cannot be easily attributed to poor filtration. Temporary fluid filtration is an excellent option to reduce or eliminate many operational issues caused by contamination.

The separation of solids from a liquid phase is an extremely common operation. There are numerous examples of this process, including:

- Removal of solids from boiler feed water

- Removal of microscopic particulate from lubrication oil

- Filtration of finished products to meet quality specifications

The four possible outcomes of the filtration of a solid/liquid stream are:

- Recovery of the liquid phase

- Recovery of the solid phase

- Recovery of both the solid and liquid phases

- Recovery of neither phase, but separation is required for disposal

The goal of filtration in the oil and gas industry is typically to remove solid contaminants from a liquid stream. One of the most effective methods of filtration is bag filtration. Bag filtration is performed by running the fluid that requires cleaning through a filter vessel. This specially designed vessel holds temporary bag filters that remove the solid contaminant from the liquid stream. Some bag filters are also capable of separating small amounts of oil from water. When the bag filters become caked with a solid contaminant, they can easily be removed and replaced with new, clean filter bags. Similar to bag filtration is cartridge filtration, which uses slightly more complex filter elements in place of the bags. Each cartridge has a cylindrical construction with a rigid frame, around which the filtration fabric or material is wrapped.

Not All Filters Are Created Equal

Filters have various levels of efficiency. Just because a filter is rated to a specified micron level doesn’t mean that it is able to capture 100% of particles of that size. There are two terms used to describe filter effectiveness: absolute and nominal. Filter manufacturers usually define absolute filters as those with the ability to capture more than 98% of particles down to a specific size. For example, a five-micron absolute filter will remove at least 98% of the particulate contaminants from the fluid stream in a single pass. Nominal filters vary widely in efficiency. Typically, efficiencies for nominal rated filters are greater than 50%, but less than 98%. It is important to remember that there is no industry standard for the efficiency of nominal filters; the performance will vary from manufacturer to manufacturer. It must also be kept in mind that process conditions such as temperature, pressure, and flow rate can affect the filter performance. Always ensure that the filter element is being operated within the manufacturer’s guidelines.

When working with fluids that require high levels of cleanliness such as hydraulic and lubrication oil, the size of particulate that must be removed from the oil is in the microscopic range. This is easily accomplished with bag or cartridge filtration.

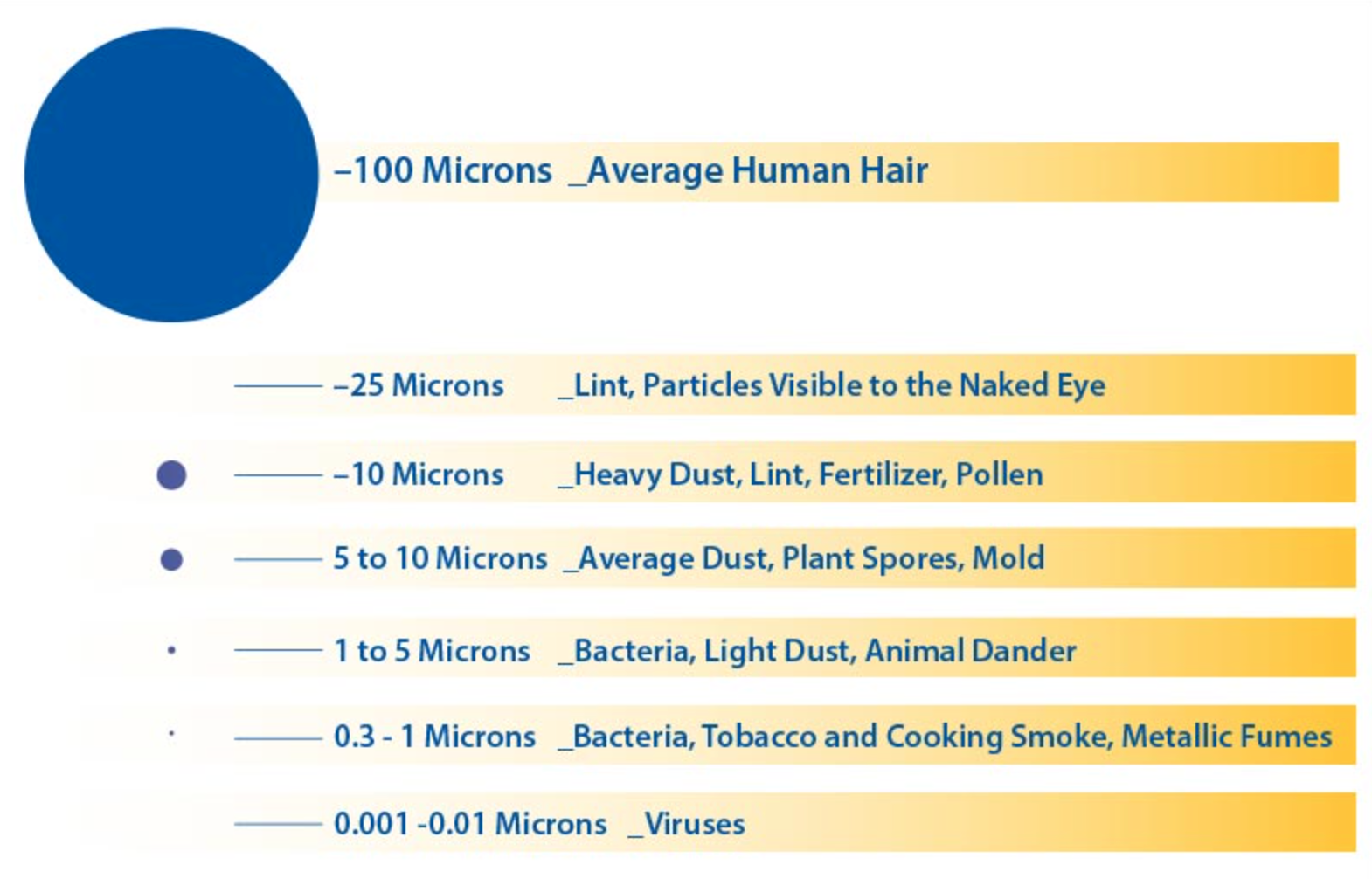

ISO Standard 4406:1999, which deals with contamination in hydraulic fluids, requires solid particles as small as four microns in size to be filtered out of the oil. In order to gain an appreciation for the size of these particles, the following chart shows the relative sizes (to scale) of some common particulates:

A micron or micrometre (μm) is one thousandth of a millimetre, or 0.00004 inches. The smallest particle visible to the average naked eye is 25 μm; the average diameter of human hair is around 100 μm; a dust particle is 25 μm; and bacteria are between 0.2 and 11 μm. Conventional bag or cartridge filtration is able to remove particles down to the 1 μm range.

Benefits

In order to prevent premature equipment failure caused by plugged lines or damaged bearings, the filtration of hydraulic and lube oil systems is critical prior to system startup. Most manufacturers of this type of equipment have their own guidelines for completing pre-startup filtration. Temporary filtration can also be performed on water and condensate systems prior to system startup and during operations to eliminate contaminants both large and small. The goal of filtration is to stop materials from contaminating a system before they cause damage, downtime, or failure. Temporary filtration is an inexpensive way to keep processes and equipment running efficiently for a long time.